Air suspension system maintenance

The 600 as well as the 300 SEL (3,5 and 6,3) and the 300 SE model have an air suspension system. With this system it is possible, depending on the loading, to keep the toe and camber in alignment.

The system actually functions very dependably.

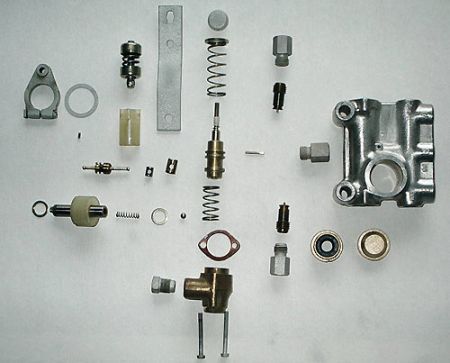

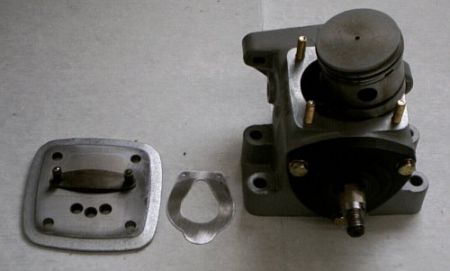

However many W 100 and W 109 have problems with the air suspension. This is because of the age of the parts. The single O-rings and rubber seals harden or tear. This causes air to escape from the system and the car to be lower.

An air suspension system that functions properly should maintain pressure and consequently the car level for many months !!!